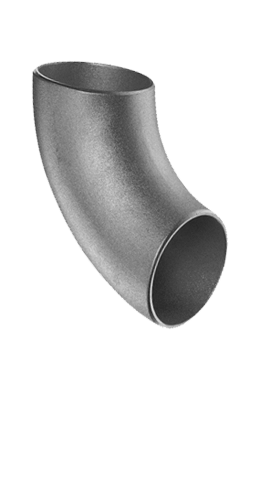

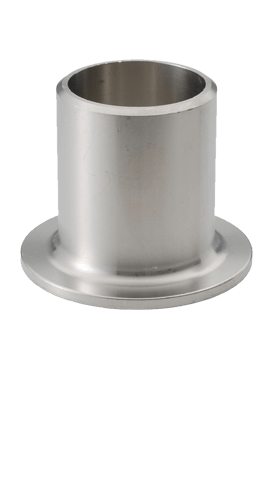

Stainless Steel 904L Butt weld Fittings, SS 904L Butt weld Elbow Exporter, ASTM A403 Stainless Steel 904L Equal Tee, SS 904L Reducer, SS 904L Pipe Cap Supplier, Stainless Steel 904L Pipe Elbow, Stainless Steel 904L Pipe Bend, SS WP904L Pipe Fittings in Mumbai, India.

Dinesh Tube Indian is a leading supplier and stockholder of the SS 904L Pipe Fittings at comprehensive range It means one can buy it as per own desires in various wall thickness and sizes etc. They catering to the needs and budget of buyers are supplying it at reasonable rates addition to sales after services.

SS 904L Pipe Fittings, SS 904L Long Radius Elbow, ANSI B16.9 Stainless Steel 904L Welded Pipe Fittings Supplier, ASME SA403 Stainless Steel 904L Cross Stockists, Stainless Steel WP904L Pipe Nipple, Stainless Steel 904L Seamless Pipe Fittings, SS 904L Stub End in India.

This high alloy SS 904L Pipe Fittings is additional with copper to get better its resistance to tough reducing acids, such as sulphuric acid. The steel is also opposed to stress corrosion cracking and crack corrosion. Grade 904L is non-magnetic and offers exceptional formability, toughness, and weldability. Grade 904L Stainless steel is a non-stabilized austenitic Stainless steel with little carbon content. This high alloy Stainless steel is extra with copper to improve its resistance to tough reducing acids, such as sulphuric acid. The steel is also opposing to stress corrosion cracking and crevice corrosion. Grade 904L is non-magnetic and offers exceptional formability, toughness, and weldability.

Grade 904L contains elevated amounts of exclusive ingredients, such as molybdenum and nickel. Today, mainly of the applications that employ grade 904L are replacing by low-cost duplex Stainless steel 2205.

Grade 904L Stainless steels have exceptional resistance to warm salt water and chloride attack. The high conflict of grade 904L against stress corrosion crack is due to the presence of high amounts of nickel in its composition. Moreover, the adding of copper to these grades develops resistance to sulphuric acid and other falling agents in both aggressive and mild conditions.

The corrosion resistance of grade 904L is middle between super austenitic grades, with 6% molybdenum satisfied and standard 316L austenitic grades. Grade 904L is less opposed to nitric acid than grades 304L and 310L, which are open of molybdenum. This steel grade needs to be way out treated following cold working, to attain maximum stress corrosion cracking resistance below critical environments.

Grade 904L Stainless steels suggest good oxidation resistance. However, the structural strength of this grade collapses at elevated temperatures, particularly above 400°C.

Grade 904L Stainless steels preserve be solution heat-treated at 1090 to 1175°C, following by fast cooling. Thermal treatment is appropriate for hardening these grades.

Grade 904L Stainless steels are elevated purity steels with low sulfur content. They can be machined using any normal methods. These grades can be readily twisted to a small radius below cold conditions. Although subsequent annealing is not necessary in most cases, it must be carried out when the fabrication is performed below severe stress corrosion cracking conditions.

Equivalent Grades