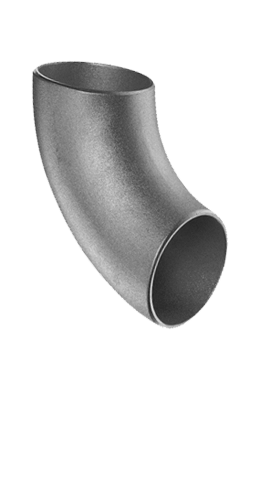

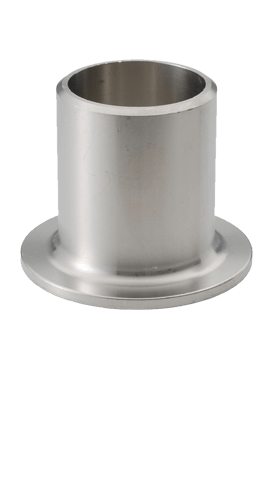

SS 310H Butt weld Elbow Exporter, SS 310H Reducer, SS WP310H Pipe Fittings, Stainless Steel 310H Pipe Bend, ASTM A403 Stainless Steel 310H Equal Tee, SS 310H Pipe Cap Supplier, Stainless Steel 310H Butt weld Fittings, Stainless Steel 310H Pipe Elbow in Mumbai, India.

SS 310/310S Pipe Fittings Grade 310 is an average carbon austenitic Stainless steel, for elevated temperature applications such as heater parts and heat treatment equipment. It is used at temperatures up to 1150°C in incessant service, and 1035°C in irregular service. Grade 310S is a low carbon side of grade 310. These grades have 25% chromium and 20% nickel, making them extremely resistant to oxidation and corrosion. Grade 310S is a lower carbon version, less level to embrittlement and sensitization in service.

Stainless Steel WP310H Pipe Nipple, Stainless Steel 310H Seamless Pipe Fittings, SS 310H Stub End, ASME SA403 Stainless Steel 310H Cross Stockists, SS 310H Pipe Fittings, SS 310H Long Radius Elbow, ANSI B16.9 Stainless Steel 310H Welded Pipe Fittings Supplier in India.

The high chromium and average nickel content make these steels able for applications in falling sulfur atmospheres containing H2S. They are widely used in fairly carburizing atmospheres, as an encounter in petrochemical environments. For more severe carburizing atmospheres other heat resists alloys should be selected. Grade 310 is not recommended for recurrent liquid quenching as it suffers from thermal shock. The grade is frequently used in cryogenic applications, due to its hardiness and low magnetic permeability.

In common with extra austenitic Stainless steels, these grades cannot be toughened by heat treatment. They can be toughened by cold work, but this is rarely practiced.

The Stainless steel 310/310S also contain elements like Carbon, Manganese, Silicon, Phosphorus, Sulphur, Chromium, and Nickel.

Features: Grade 0.2% Proof Stress Mpa, Tensile Strength Mpa, Elongation%, Hardness (HV)

Fabrication of Grade 310/310S: Fabrication Grades 310/310S are forged in the temperature range 975 - 1175°C. Heavy work is carried out down to 1050°C and a light finish is applied to the bottom of the range. After forging, annealing is optional to relieve all stresses from the forge process. The alloys can be gladly cold formed by normal methods and equipment.

Welding of Grade 310/310S, Welding Grades 310/310S are welded with matching electrodes and filler metals. Preheat and post heats are not necessary but for corrosion service in liquids filled post weld solution annealing action is essential. Pickling and passivation of the outside to remove high-temperature oxides are necessary to restore full aqueous decay resistance after welding. This treatment is not required for elevated temperature service, but welding slag must be thoroughly removed.

Heat Treatment: Heat treatment type 310/310S are answer annealed by heat to temperature range 1040-1065°C, hold at temperature until thoroughly soaked, and then water quenching.

Ordering the SS 310/310S Pipe Fittings from Dinesh Tube India will be beneficial as they are specialized in supplying quality of fittings. To the buyer’s product are offered at different standards, specifications and at market leading costs.

Equivalent Grades