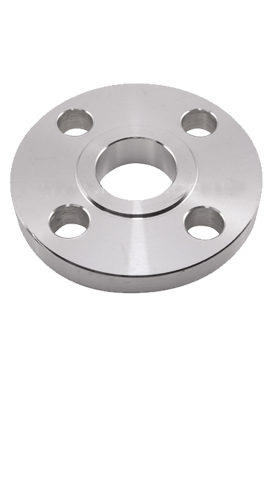

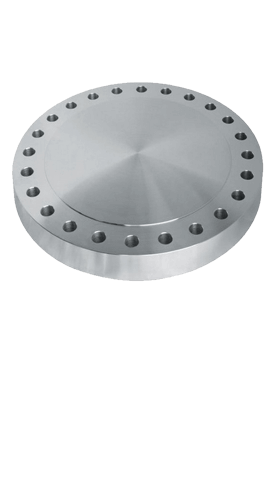

Alloy 20 Flanges Exporter, ASTM B462 Alloy 20Cb-3® Socket weld Flanges, Alloy 20 Weld Neck Flanges, Carpenter 20 Flanges, Alloy 20 Blind Flanges, Carpenter 20 Flanges Supplier, Alloy 20 Slip on Flanges, Incoloy® alloy 20 Lap Joint Flanges in Mumbai, India.

Dinesh Tube India is highly admired all across the globe and is fully involved in making and proposing the ranges of Alloy 20 Flanges. They as a producer, supplier, stockiest and exporter to the global buyers are delivering the flanges at suitable rates. Respect to several product quality standards, they are offering the flanges at various standard and custom made specifications. It is offered to the buyers at custom made specifications so that all applications desires can be fulfilled. It is varied in standards, dimensions, pressure, classes, sizes, grade, specifications etc.

Alloy 20Cb-3® Long Weld Neck Flanges, ASME SB462 Alloy 20Cb-3® Threaded Flanges Stockists, Alloy 20 RTJ Flanges, ANSI B16.5 Carpenter 20 Spectacle Blind Flanges Supplier, Alloy 20 Pipe Flanges, Alloy 20Cb-3® Flanges in India.

Alloy information-

Alloy 20 is super alloy chromium, nickel and iron-based austenitic alloy that is developed with the other essential alloying elements like molybdenum and copper. It thus provides resistance ability to the hostile atmosphere, crevice corrosion and pitting. Also, it is stabilized with the columbium alloy in order to minimize carbide precipitation at the time of welding.

The alloy 20 appears to fall in between nickel and Stainless category as it is having both alloys features. It is designed in order to offer max resists against acid attacks and is also demonstrating excellent resistant to SCC. It is also having good general corrosion resistant ability to chloride SCC and sulfuric acid. Alloy 20 is having excellent mechanical properties at elevated temperature and at ambient temperature.

Flanges manufacturing-

The Alloy 20 Slip on Flanges are developed at the manufacturing unit by using the purest quality of raw materials collected from reputable mills. The use of latest technology and modern tools help the producers in making the flanges of very good quality. With the assistance of a professional expert team, the flanges production has become quite effective as they guide the workers at all levels of production stages. This assures makers in making excel the quality of flanges. Flanges are developed as per set norms of industries and product quality standards.

Testing of the flanges-

The testing of the Alloy 20 Weld Neck Flanges is conducted with full efforts and using essential tools for easily checking the product quality. The ranges of tests done are included positive material identification test, mechanical test, chemical test, flattening-flaring test, macro-micro test, Intergranular corrosion test etc.

Equivalent Grades