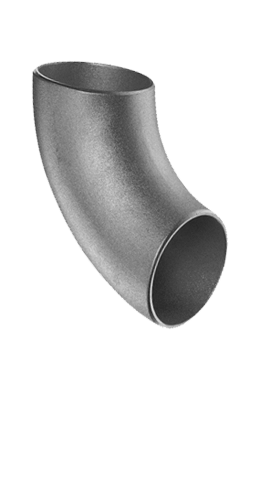

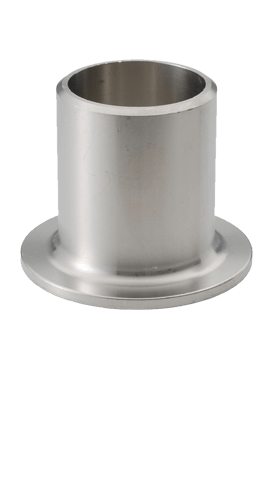

SS 304 Reducer, Stainless Steel 304L Pipe Bend, SS 304L Pipe Cap Supplier, ASTM A403 Stainless Steel 304 Equal Tee, Stainless Steel 304 Butt weld Fittings, Stainless Steel 304H Pipe Elbow, SS 304L Butt weld Elbow, SS WP304 Pipe Fittings Exporter in Mumbai, India.

Stainless steel 304/304L/304H is the austenitic SS alloy that comes under the series of 300. It is chromium and nickel-based austenitic alloy that is used in making industrial goods. Dinesh Tube India is leading to the top as a manufacturer, supplier, and exporter as well as stockiest of qualitative ranges of Stainless Seel 304/304L/304H Pipe Fittings.

SS 304 Long Radius Elbow, Stainless Steel 304 Seamless Pipe Fittings, SS 304L Stub End, ASME SA403 Stainless Steel 304H Cross Stockists, Stainless Steel WP304L Pipe Nipple, SS 304H Pipe Fittings, ANSI B16.9 Stainless Steel 304L Welded Pipe Fittings Supplier in India.

SS 304 is 18/8 standard austenitic SS that is non-magnetic at the annealed situation and by cold working operation it becomes magnetic. SS 304L is having an oxidation at the temperature of 899 Deg C constantly without scaling. It is a low carbon variety and is used frequently as the as-welded condition at severe corrosive atmosphere. SS 304H is having high carbon in it thus making it ideal for use in the applications that need high temperature.

SS 304 is 18/8 standard austenitic SS that is non-magnetic at the annealed situation and by cold working operation it becomes magnetic. SS 304L is having an oxidation at the temperature of 899 Deg C constantly without scaling. It is a low carbon variety and is used frequently as the as-welded condition at severe corrosive atmosphere. SS 304H is having high carbon in it thus making it ideal for use in the applications that need high temperature.

The manufacturing of Stainless Steel 304 Seamless Pipe Fittings is done under the strict supervision of the professional expert team. They at all levels of production of pipe fittings are guiding the workers to bring out the high quality of product that assures reliability and longevity. The quality control team is also available that is helping in maintaining the product quality to make sure that no poor quality of pipes is developed.

Qualities of the pipe fittings-

There are many good qualities found in the same that is due to the proper use of a high quality of the alloy. It has good welding and forming properties, deep drawing quality, resistant to corrosion/oxidation, greater toughness. Also, it possesses the beauty of appearances, ease of cleaning, fabrication ease and the combination of good fabricability and strength.

Testing of the material-

At the operational unit, the testing of the pipe fittings is done to check its quality. The testing done is PMI test, IGC test, hardness test, pitting resistance test, mechanical test, chemical test, flaring test, flattening test, macro/micro test.

The packaging of the pipe fittings-

Stainless steel 304/304L/304H Welded Pipe Fittings during the time of shipping need to pass through the various the channels and thus the chances of getting damages become more. So, in order to prevent the same from getting sever damages, it is packed in wooden boxes, carton boxes and is wrapped in environmental poly bags.

Equivalent Grades