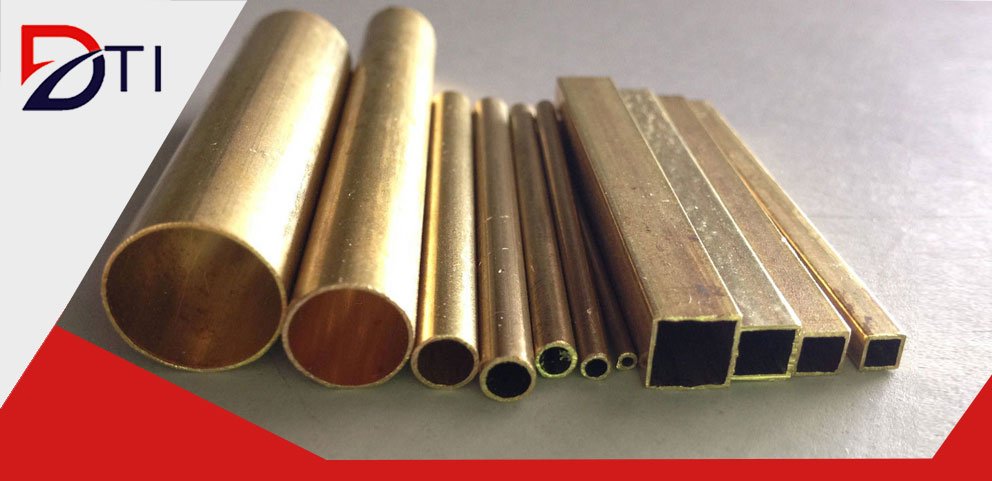

63/37 Brass Tubes, 63/37 Brass Tubing, Exporter Of 63/37 Brass Tubes, ASTM B135 63/37 Brass Seamless Tubes, 63/37 Yellow Brass Tubes, Yellow Brass C27400 Tubing Stockist, Brass 63/37 Welded Tubes, UNS C27400 Tubes, 63/37 Brass Alloy Tubing Best Price, Industrial 63/37 Brass Tubes Supplier in Mumbai, India.

Dinesh tube India is leading supplier, and exporter of 63/37 Brass Tubes that are known as the most common used the brass product. These tubes are widely used in industries because of their high quality and durability. The 63/37 brass is basically copper and zinc-containing alloy with a comprehensive range of engineering uses.

Table of Content

- What is 63/37 Brass Tubes

- Standard Specification For 63/37 Brass Tubes

- Types Of 63/37 Brass Tubing

- Chemical Composition of 63/37 Brass Tubes

- Mechanical Properties of 63/37 Brass Tubes

- Widest Stock of 63/37 Brass Tubes

- Application for 63/37 Brass Tubing

- People Also Searched for

- Export Destinations for 63/37 Brass Tubes

63/37 Brass Alloy Tubes, 63/37 Brass Seamless Tubes, Brass 63/37 Tubes, High Quality of 63/37 Brass Tubes, 63/37 Yellow Brass Tubing, ASME SB 135 63/37 Brass Alloy Seamless Tubing, C27400 Brass Tubes, Yellow Brass C27400 Tube, 63/37 Brass Tubes Stockholder, 63/37 Brass Tubing Exporter in India.

The addition of zinc with copper increases the strength and offer a wide range of properties. The alloy is often used due to its strength, appearance, corrosion resistance, color, joining and ease of working.

The tubes manufactured using this alloy is easy to clean and have various excellent features and properties. There are some other features also that are included such as excellent performance, corrosion resistance, superior durability, superior rust-proof finishing, accurate dimensions, and rugged construction.

Dinesh tube India is the reputed manufacturing company that manufactures high quality of 63/37 Brass Tubes. You can buy these from us in different shapes, sizes, forms and specifications as per the requirement of customers. While manufacturing these tubes we make use of high-quality raw material. The material we use for manufacturing is well inspected and tested by the experts so that no defected material is used for manufacturing.

In addition to the raw material, tested machines, tools, and advanced technologies are used by the professionals to create accurate shape, size, and form of tubes. All grades and types of tubes have excellent surface finishing which makes them suitable for all types of application.

When these 63/37 Brass Tubes are fully manufactured, they come across various tests and inspections. The complete testing process takes place under the observation and guidance of quality inspection agencies. These tubes are tested under different temperature range so as to check the quality of these tubes. The tests include drift test, flattening, flaring test, Mercurous nitrate test, hydraulic test, third-party inspection, IGC test, positive material identification test and more.

After the testing processes, these 63/37 Brass Tubes are packed in bundles that helps avoid damages until they are sent to their respective customers worldwide.

Chemical Composition

Mechanical Properties

Other Types Of 63/37 Brass Tubes

63/37 Brass Tubes Application Industries