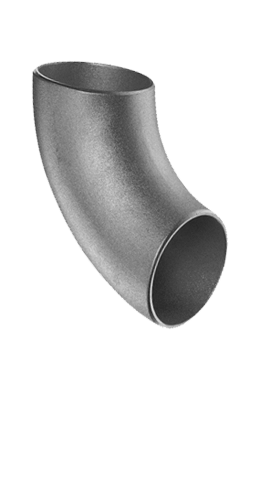

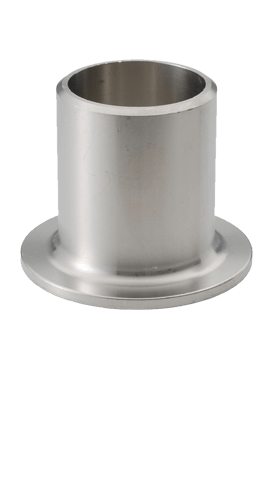

Sanicro 28 Butt weld Elbow Exporter, Sanicro 28 Reducer, SS N08028 Pipe Fittings, Sanicro 28 Pipe Bend, ASTM A403 Sanicro 28 Equal Tee, Sanicro 28 Pipe Cap Supplier, Sanicro 28 Butt weld Fittings, Sanicro 28 Pipe Elbow in Mumbai, India.

SANICRO 28 Pipe Fittings is a high-alloy multi-purpose austenitic Stainless steel for repair in highly corrosive conditions. The grade is characterized by-Very high corrosion conflict in strong acids, Very good conflict to stress corrosion cracking (SCC) and intergranular corrosion is existing in various environments.

Stainless Steel N08028 Pipe Nipple, Sanicro 28 Seamless Pipe Fittings, Sanicro 28 Stub End, ASME SA403 Sanicro 28 Cross Stockists, Sanicro 28 Pipe Fittings, Sanicro 28 Long Radius Elbow, ANSI B16.9 Sanicro 28 Welded Pipe Fittings Supplier in India.

Due to embrittlement caused by precipitation of inter metallic phases, SANICRO 28 must not be exposed to temperatures exceeding 600 °C (1110 °F) for prolonged periods. According to the ASME Boiler and force Vessel Code Table 1B, SANICRO 28 is suitable to 600ºF (316ºC) for Section III construction and 850ºF (455ºC) for Section I (Code Case 1325-18) and part VIII, Division 1 construction. Tube, pipe, plate, and sheet with substance thicknesses

SANICRO 28 was initially developed for use in the production of phosphoric acid, particularly for heat exchangers in the attention unit, where corrosive are at their worst.

SANICRO 28 resists hydrofluoric and hydrofluosilicic acid extremely well and can be used wherever these acids occur as impurities. Equally, SANICRO 28 and AISI 316L are totally resistant to pure acetic acid at all temperatures and concentration at atmospheric pressure. However, at important temperatures and pressures, AISI 316L will decay while SANICRO 28 will remain resistant.

Acetic acid is often impure with formic acid, which renders it extra corrosive. Laboratory tests show that SANICRO 28 is extra resistant than AISI 316 and AISI 317L in such solutions. SANICRO 28 is far extra resistant to formic acid than conservative Stainless steels of the AISI 316L type and extra resistant than 904L. In nitric acid SANICRO 28 performs also extremely well. In a test according to ASTM A262 Practice C (Huey test, 5x48 h in boiling 65% HNO) decay rates lower than 0.15 mm/year (6 mph) is obtained.

At high temperatures the common corrosion rate increases. The risk of pressure corrosion cracking (SCC) also increases while chlorides are present. Demonstrate the good conflict of SANICRO 28 against general corrosion and SCC in sodium hydroxide impure with chlorides.

Laboratory tests show that SANICRO 28 has good conflict to crevice corrosion. In tests according to ASTM G48 technique B (6% iron (III) chloride) the material exhibited improved resistance than Alloy 825.

Dinesh Tube India is a prominent supplier of the SANICRO 28 Pipe Fittings at wider range varying in specifications, standards and dimension. They as provides product at reasonable rates to buyers so dealing with it will be beneficial.

Equivalent Grades