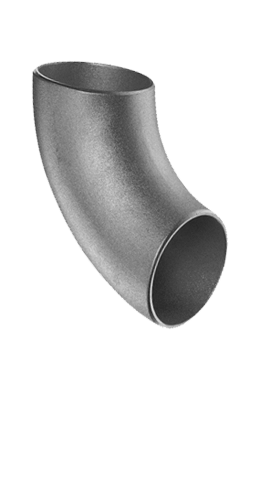

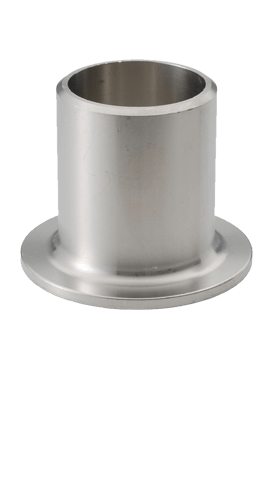

ASTM A403 Stainless Steel 316Ti Equal Tee, SS 316Ti Reducer, SS 316Ti Pipe Cap Supplier, SS WP316Ti Pipe Fittings, SS 316Ti Butt weld Elbow Exporter, Stainless Steel 316Ti Pipe Bend, Stainless Steel 316Ti Butt weld Fittings, Stainless Steel 316Ti Pipe Elbow in Mumbai, India.

SS 316Ti is the most stable grade of the SS 316 alloy. 316Ti is highly suitable for pervasive situations. Characteristics of these grade exhibit nearly the same general properties as the 316 grade. It has a slight content of titanium that helps in protecting it from precipitation at high temperatures. The presence of good quality molybdenum in the 316Ti grade offers excellent resistance to corrosion, pitting resistance to chloride environment, good strength at high temperatures and exceptional durability.

ANSI B16.9 Stainless Steel 316Ti Welded Pipe Fittings Supplier, SS 316Ti Stub End, SS 316Ti Pipe Fittings, Stainless Steel 316Ti Seamless Pipe Fittings, ASME SA403 Stainless Steel 316Ti Cross Stockists, Stainless Steel WP316Ti Pipe Nipple, SS 316Ti Long Radius Elbow in India.

Dinesh Tube India is one of the leading exporters, manufacturers and stockist of top-notch SS 316TI Pipe Fittings. This alloy is resistant to acidic situations such as hydrochloric, sulfuric, and sulfuric. We deliver all over the world with their efficient packaging methods. Moreover, the raw materials used by the industry are procured from the market vendors that ensure their delivered products. The sector uses modern machinery and other latest technology to enhance the productivity of the pipe fittings. They are engaged in offering complete customer satisfaction regarding quality, performance, longevity, and affordable price of pipe fittings. To maintain the quality and efficiency of the pipe fittings, we keep upgrading their products according to market trends and customer demands.

The industry conducts several material tests on SS 316TI Pipe Fittings in order to ensure the quality before finale delivering it to the customers across the world. The tests performed are mechanical test, positive material identification, intergranular corrosion test, pitting resistance test, flaring test, flattening test, micro and macro test and chemical analysis are some of the important tests performed. We conduct several testing on SS 316TI Pipe Fittings in order to ensure the quality before delivering it to customers across the globe. The tests performed are mechanical tests, positive material identification, intergranular corrosion test, pitting resistance tests, flaring tests, flattening tests, micro and macro test and chemical analysis are some of the important tests performed.

We also offer documents and certificates that help the buyers to authenticate the product. Heat treatment charts, self-inspection reports, commercial invoices, lab reports, third-party inspection, material test certificates, sanitize certificates, and radiography test reports with theSS 316TI Pipe Fittings.

Equivalent Grades