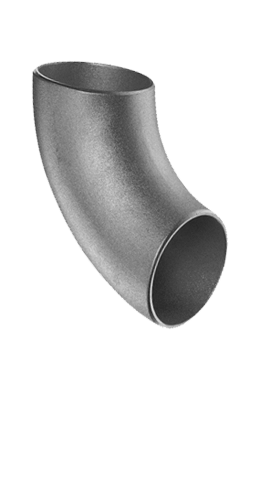

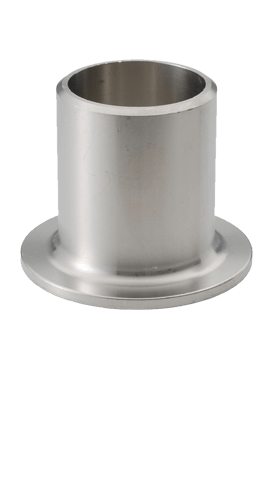

Alloy 20Cb-3® Pipe Fittings, Alloy 20 Pipe Cap Supplier, Alloy 20 Butt weld Elbow, Alloy 20 Reducer, Incoloy® alloy 20 Pipe Elbow, Alloy Alloy 20 Pipe Bend, Carpenter 20 Butt weld Fittings, ASTM B366 Carpenter 20 Equal Tee Exporter in Mumbai, India.

Alloy 20 is an austenitic Stainless Steel which is highly useful in the manufacturing of pipe fittings due to its unmatched qualities. The grade offers excellent corrosion resistance, general corrosion resistance, pitting resistance to chloride environment and crevice resistance. Alloy 20 is better than any other alloy grade because they are columbium stabilized that makes it useful in extensive high temperature.

ANSI B16.9 Alloy 20 Welded Pipe Fittings, Alloy 20 Long Radius Elbow, ASME SB366 Alloy 20Cb-3® Cross, 20 Alloy Pipe Fittings, Carpenter 20 Seamless Pipe Fittings Stockists, Incoloy® alloy 20 Stub End, Alloy 20 Pipe Nipple Supplier in India.

There are many good chemical components present in the alloy due to which the grade offers good ease to workability, weldability, and strength. The fittings manufactured using this grade makes them durable in the tough environmental situation and useful for many piping systems. Dinesh Tube India is one of the largest manufacturer, exporter, and supplier of high-quality ALLOY 20 Pipe Fittings which are offered to the customers across the world. The industry uses efficient quality of raw materials that help in enhancing the quality and other attributes of the pipe fittings. Besides, the buyers prefer to buy the products from them due to their valuable services offered.

The industry provides high-end finishing, accurate dimensions and timely delivery of the goods. The machines used in manufacturing are highly modern. They are engaged in offering complete customer satisfaction to their customers when it comes to quality, efficiency, performance and affordable price of the pipe fittings.

Dinesh Tube India offers tests certifications such as manufacturer TC in conformance with EN 10204, raw material report, third-party inspection, radiography test reports, and other inspection reports are provided along with the pipe fittings. Apart from this, there are several tests conducted by the trained professionals in order to ensure the quality of the pipe fittings before dispatching it to the clients. Material tests such as mechanical test, PMI tests, IGC test, pitting resistance test, micro and macro test, flaring test, flattening test and bend test are some of the relevant material tests performed.

Talking about the packaging of the ALLOY 20 Pipe Fittings the industry uses wooden crates, cases or pallets that are free from fumigation and other impurities. Moreover, the sector offers relevant shipping documents and briefs with the clients to complete all the documents formality.

Equivalent Grades