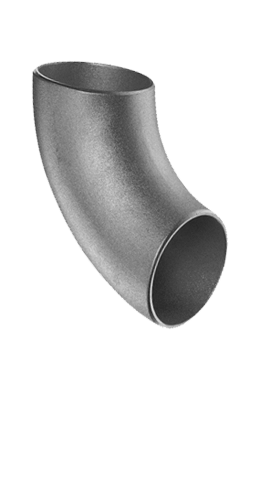

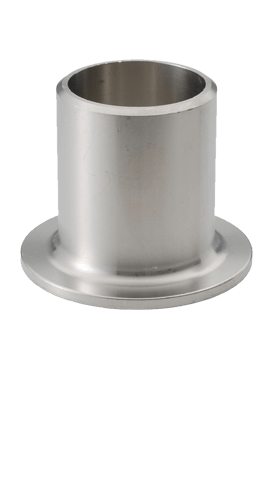

SS 321H Pipe Cap Supplier, Stainless Steel 321H Pipe Elbow, Stainless Steel 321 Butt weld Fittings, Stainless Steel 321H Pipe Bend, SS 321H Butt weld Elbow, ASTM A403 Stainless Steel 321 Equal Tee Exporter, SS 321 Reducer, SS WP321 Pipe Fittings in Mumbai, India.

We dinesh Tube India is leading on the top as supplier and stockiest of 100% pure quality of SS 321/SS 321H Pipe Fittings. We offer the product at custom made and standard specification. It means it is made available at different shapes, wall thickness and sizes etc and is supplied at factory rates. Stainless steel 321 is the stabilized description of Stainless steel 304. The 18/8 combine of chromium and nickel is tempered with titanium to provide type 321 protection from intergranular corrosion that can occur later than heat treatment.

Stainless Steel WP321H Pipe Nipple, SS 321H Stub End, Stainless Steel 321 Seamless Pipe Fittings Supplier, SS 321 Long Radius Elbow, ASME SA403 Stainless Steel 321H Cross Stockists, ANSI B16.9 Stainless Steel 321H Welded Pipe Fittings, SS 321H Pipe Fittings in India.

It is sheltered from temperatures ranging from 800 to 1500°F. The metal displays high power and resistance to various forms of corrosions, including that from aqueous environments. Type 321 finds application in serious welding components, along with dynamic environments that are subject to changes.

However, the adding of titanium limits the application of 321 in conditions of working. The metal is not optional for certain welding techniques as it is not consumable. Beyond this, Stainless steel 321 has outstanding forming characteristics, does not need annealing after being welded, and displays roughness in a range of temperatures. The metal shows power even when exposed to cryogenic temperatures. Additionally, it is often selected over Type 304 for its increased resistance to creep and rupture. Both metals can be susceptible to stress corrosion cracking.

Stainless Steel 321H is the higher-carbon change of Stainless steel 321. In addition, 321H is stabilizing by an adding up of niobium to resist intergranular corrosion. It is also able to survive higher temperatures than type 321, due to its important carbon levels. While 321H displays the similar welding and forming characteristics of type 321, the metal cannot be hardened by heat treatment. It is utilized in situations where type 321 cannot withstand the elevated temperatures, typically those exceeding 1000° F. Type 321H displays improved resistance against creep than together 321 and 304 Stainless sheets of steel.

321H also shows resistance next to acid corrosion in a variety of environments. Lower temperatures provide improved resistance, but the metal is able to survive up to a 10% acid solution, that has been diluted, at important temperatures. However, the metal shows very little resistance next to chlorine or sulfuric solutions at any given temperature. Given their like composition and characteristics, it is likely for Stainless steels 321 and 321H to become dually certified.

Alloy 321 exhibits good quality general corrosion resistance that is similar to 304. It was developed for use in the chromium carbide rainfall range of 1800-1500°F.

Equivalent Grades