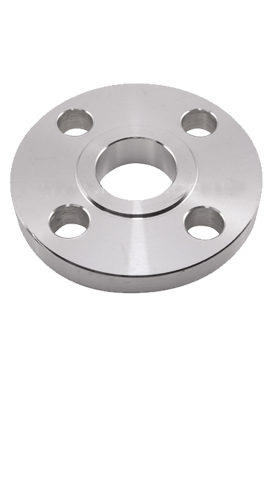

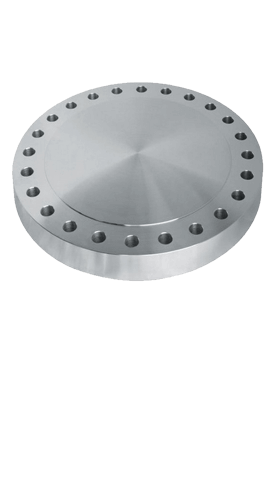

Stainless Steel 321H Flanges, SS 321H Lap Joint Flanges, SS 321H Blind Flanges, SS 321 Flanges Exporter, SS 321 Weld Neck Flanges, ASTM A182 Stainless Steel 321 Socket weld Flanges, SS 321H Flanges Supplier, Stainless Steel 321 Slip on Flanges in Mumbai, India.

Dinesh Tube India is a leading supplier, extensive stockiest of fitting equipment. We manufacture the whole range of SS products including SS 321 / SS 321H Flanges. It is vastly demanded by the customers because of its good attributes. We deliver these products to national and international customers. We also supply nonstandard size products to customers as per their application requirements. We are committed to serving customers sourcing needs of the above flanges with high quality as well as customer service.

ASME SA182 Stainless Steel 321H Threaded Flanges Stockists, SS 321H Pipe Flanges, SS 321H Flanges, ANSI B16.5 SS 321H Spectacle Blind Flanges Supplier, Stainless Steel F321H Long Weld Neck Flanges, SS 321 RTJ Flanges, Stainless Steel 321 Flanges in India.

Technical data-

This alloy is titanium stabilized alloy from the family of austenitic SS with good corrosion resistance ability. These have good resistance to intergranular corrosion in the exposure to the temperature range between 427 to 816 degree C. it is resistive to towards chromium carbide precipitation. These flanges resist oxidation up to 816 degree C and have higher creep and stress rupture strength. It also possesses good low-temperature toughness. This alloy has also known as UNS S321109 alloy.

It has developed for enhanced creep resistance and higher strength at temperatures above 537 degree C. in most of the cases the carbon content of flanges enables dual certifications. These are not treatable with the heat treatment process; however, the cold working process is induced for extra hardening. These are easily weldable with all standard welding process.

These possess good machinability, fabricability, formability and workability feature that makes it best option for low-cost fabrication applications. The cold work hardening rate makes it machinable with low cutting speeds, feeds and cut depths. These flanges are quite ductile and form easily. These are hot formed in the temperature range between 1149 – 1260 degrees C. fabricated products are processed from water quenching process to hold good mechanical properties. This also re-attains the maximum corrosion resistance.

At Dinesh, Tube India believes that quality is a crucial part of continued development to stay closer to customer’s demands. We are known for quality assurance and reliability reports offered to customers. Some reports are raw material test report, mill test report, NABL test report, specification guide, product invoice, and guarantee letter.

SS 321 / SS 321H Flanges are offered by us in good tolerance limit and machining allowance, one can use it for multiple applications.

Equivalent Grades