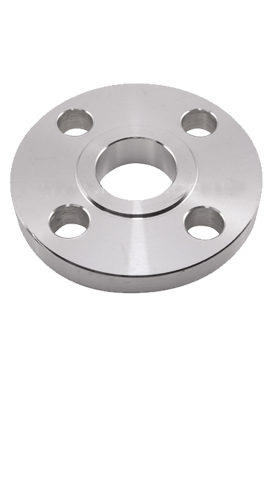

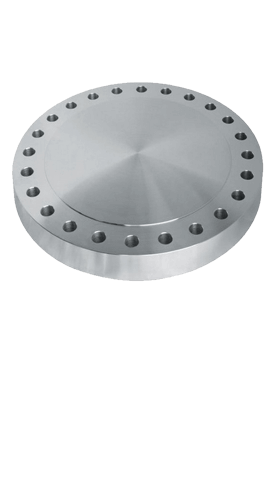

Stainless Steel 317 Slip on Flanges, Stainless Steel 317L Flanges, SS 317 Weld Neck Flanges, SS 317L Blind Flanges, SS 317L Lap Joint Flanges, SS 317L Flanges Supplier, SS 317 Flanges Exporter, ASTM A182 Stainless Steel 317 Socket weld Flanges in Mumbai, India.

Dinesh Tube India is the pioneer trading place of SS 317/317L Flanges, which is known for its compatibility in adverse environments. We are engaged in supplying, exporting and distribution of SS grade flanges. Our inventory of filled with SS flanges in various grades, specifications and custom dimensions. Therefore, one can get their products as per their suitability and requirements. It is a low carbon version of corrosion resistant alloy. The chemical compositions present are chromium, molybdenum and nickel content.

SS 317L Flanges, SS 317 RTJ Flanges, SS 317L Pipe Flanges, ANSI B16.5 SS 317L Spectacle Blind Flanges Supplier, ASME SA182 Stainless Steel 317L Threaded Flanges Stockists, Stainless Steel F317L Long Weld Neck Flanges, Stainless Steel 317 Flanges in India.

Know about SS 317/317L Flanges:

The alloy 317L is also called UNS S31703 alloy. The high level of resisting elements assures that alloy has superior resistance to chloride, pitting and general corrosion resistance. It is the best grade than the conventional grade. This alloy provides enhanced relative in strongly corrosive environments such as sulfuric acids, sulfides, chlorides, alkalis, and other harsh chemicals. These flanges are low carbon version that enables it to be weld without intergranular corrosion resulting for use in chromium carbide precipitation. In addition to nitrogen, the alloy gets more strength.

SS 317/317L Flanges flanges are nonmagnetic in nature when annealed. This cannot be hardened by heat treatment process; however, it is hardened by the cold working process. These flanges are easily welded and processed by standard shop fabrication process.

SS 317/317L Flanges flanges are hot formed in the working temperature of 900- 1150 degree C. these are quenched rapidly with water. This version of the alloy is quite ductile and forms easily. The composition of molybdenum and nitrogen implies more powerful processing equipment. The cold work hardening rate of flange makes it machinable with low cutting speeds, feeds and cut depth.

Reliability of products-

We believe in the long term relationship with customers, as customers look for a trusted supplier who assures the quality of SS 317/317L Flanges. We provide documentation reports to customers as a manual to use flanges effectively also it is a quality proof of our products. Those reports are product invoice, specification guide, disinfection reports, packing list like quantity and marks and number, NABL test report, MTC report as per EN 10204 3.1 or 3.2 and guarantee letter. Other reports are attested certificates, raw material test report, mill test report, quality assurance plan, and heat treatment charts.

Equivalent Grades