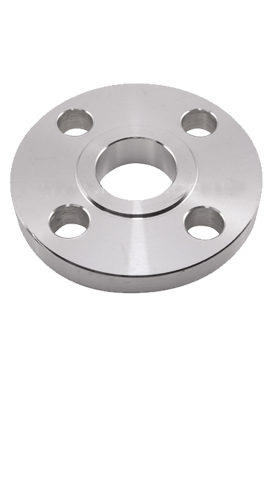

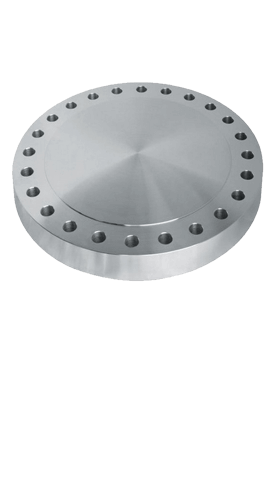

Stainless Steel 304L Flanges, SS 304 Weld Neck Flanges, SS 304L Flanges Supplier, ASTM A182 Stainless Steel 304 Socket weld Flanges, Stainless Steel 304 Slip on Flanges, SS 304H Blind Flanges, SS 304L Lap Joint Flanges, SS 304 Flanges Exporter in Mumbai, India.

SS 304/304L/304H Flanges is the normal 18/8 (18% chrome, 8% nickel) austenitic Stainless steel flanges. It is a non-magnetic alloy in the annealed situation, however, becomes magnetic as it is cold worked. It is the most normally utilized of all Stainless grades. 304 can be naturally welded and is the preferred for a lot of deep drawn, spun or formed part due to its high ductility. Dinesh tube India is the acclaimed supplier, distributor and trader of high end SS 304/304L/304H Flanges in variety of standards, specifications, designations and custom dimensions.

Stainless Steel 304 Flanges, SS 304L Pipe Flanges, SS 304 RTJ Flanges, ASME SA182 Stainless Steel 304H Threaded Flanges Stockists, Stainless Steel F304L Long Weld Neck Flanges, SS 304H Flanges, ANSI B16.5 SS 304L Spectacle Blind Flanges Supplier in India.

Stainless Steel grade 304L has corrosion resistance to a maximum temperature of 1650°F (899°C) continuous exclusive of considerable scaling. Since 304L is an extra low-carbon variety of 304 it can regularly be utilized in the as-welded situation, even in service caustic conditions, except for applications indicative of stress relief. 304L has good welding behavior and can be welded by all normal strategy; however, thought should be paid to maintain a strategic expanse from weld hot cracking. To relieve stress through severe forming or spinning welding can be followed by annealing.

Stainless Steel grade 304H include a high carbon content creation the steel more appropriate for utilization in applications where elevated temperatures are available. The profit of this grade is that is an austenitic chromium-NICKEL alloy as well as the better carbon content distribute to increased tensile and yield power. The material is suggested for utilizing ASME pressure vessels in effective service since the grade’s heat resistant properties.

SS 304/304L/304H Long Weld Neck Flanges have magnificent struggle to a corrosive environment, for instance, textile, chemical, and petroleum industries. They are establishing suitable in dairy and food industries as well as achieve exceptionally well in rural and manufacturing atmospheric exposure.

To work solidify slow speeds and serious feeds will minimize this alloy’s tendency. Because of long stringy chips, the use of chip breakers is prudent. Many organizations now offer premium machinability grades. All fusion and battle process have been successfully utilized in welding 304. AWS E/ER308 or 312 filler metal is recommended. Many users choose 304L for cleaner and stronger welds which have a prohibited low carbon designed to decrease carbide precipitation at the weld boundaries.

Equivalent Grades