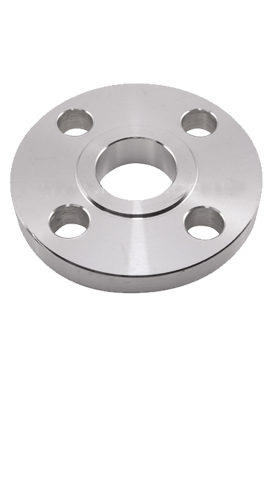

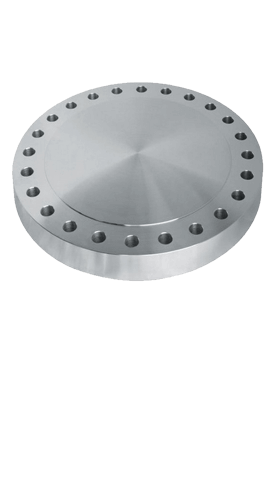

SS 310H Blind Flanges, Stainless Steel 310H Slip on Flanges, SS 310H Lap Joint Flanges, SS 310H Weld Neck Flanges, ASTM A182 Stainless Steel 310H Socket weld Flanges, SS 310H Flanges Supplier, Stainless Steel 310H Flanges, SS 310H Flanges Exporter in Mumbai, India.

Dinesh tube India is experienced in supplying, distributing and exporting whole range of SS products. We cater all the requirements of the customers regarding their application requirements. SS 310H Flanges is for significant temperature applications such as heater parts and heat treatment equipment. It is used at temperatures up to 1150°C in constant service and 1035°C in irregular service. Grade 310S is a low carbon account of grade 310.

SS 310H Flanges, SS 310H RTJ Flanges, SS 310H Pipe Flanges, ANSI B16.5 SS 310H Spectacle Blind Flanges Supplier, ASME SA182 Stainless Steel 310H Threaded Flanges Stockists, Stainless Steel F310H Long Weld Neck Flanges, Stainless Steel 310H Flanges in India.

A flange is a method of between pipes, valves, pumps and other gear to form a piping system. It also provides simple access for cleaning, going over or modification. Flanges are regularly welded or screwed. Flanged joints are made by bolt together two flanges with a gasket among them to provide a seal. Pipe flanges are contrived in all the dissimilar materials like Stainless steel, cast iron, aluminum, brass, bronze, plastic etc. but the mainly used material is forged carbon steel and has machined surfaces.

In addition like tools flanges and pipes, for exact purpose sometimes inside ready with layers of materials of a completely dissimilar quality as the flanges themselves, which are "lined flanges”. The material of a flange is essentially set during the choice of the pipe, in main cases; a flange is of the similar material as the pipe.

Hot forming:

Heat consistently at 1742–2192°F (950–1200°C) After hot form a final anneal at 1832–2101°F (1000–1150°C) followed by fast quenching is recommended.

Cold forming:

The alloy is quite elastic and forms in a manner extremely similar to 316. Cold forming of piece with long-term practice to high temperatures is not optional since the alloy is subject to carbide precipitation and sigma phase precipitants.

Welding:

Alloy 310 can be with pleasure welded by most normal processes including TIG, PLASMA, MIG, SMAW, SAW, and FCAW

Wet corrosion:

Alloy 310H is not considered for service in wet acidic environments. The high carbon content, which is present to improve creep properties, has a harmful effect on aqueous oxidization resistance. The alloy is prone to intergranular corrosion later than long term exposure at high temperatures. However, due to its high chromium satisfied (25%), Alloy 310H is extra corrosion resistant than main heat resistant alloys.

Equivalent Grades