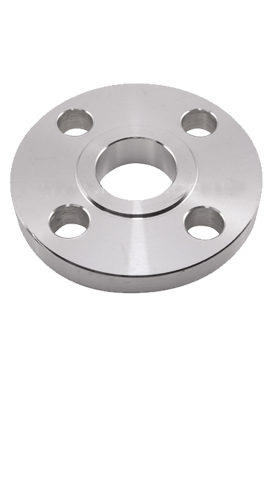

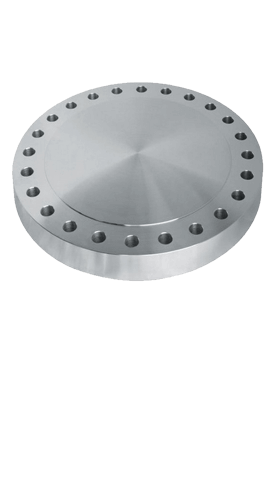

Stainless Steel 316H Flanges, SS 316H Lap Joint Flanges, SS 316H Flanges Exporter, ASTM A182 Stainless Steel 316H Socket weld Flanges, SS 316H Flanges Supplier, SS 316H Weld Neck Flanges, SS 316H Blind Flanges, Stainless Steel 316H Slip on Flanges in Mumbai, India.

At Dinesh Tube India, we deem to accomplish every requirement of customers regarding SS flanges including SS 316H Flanges. These are used to give sufficient strength to the connection and stop leakage. This flange is preferential over weld neck flanges as less exactness is required when cutting the pipe to length, the charge to produce is lower but there is almost the same outcome. It is often used in procedure streams contain chlorides or halides.

SS 316H Pipe Flanges, Stainless Steel 316H Flanges, Stainless Steel F316H Long Weld Neck Flanges, ASME SA182 Stainless Steel 316H Threaded Flanges Stockists, ANSI B16.5 SS 316H Spectacle Blind Flanges Supplier, SS 316H Flanges, SS 316H RTJ Flanges in India.

The alloy resists impressive corrosion, as well as, fairly oxidizing and reducing environments. It also resists decay in polluted marine conditions. Alloy 316H is non-magnetic in the annealed condition. Alloy 316H (UNS S31609) is a high carbon alteration of Alloy 316 developed for use in important temperature service. The alloy has higher power at elevated temperatures and is used for structural and pressure craft applications at temperatures higher than 932°F (500°C). The higher carbon satisfied of 316H also delivers elevated tensile and yield force than 316/316L and its austenitic structure provide excellent hardiness down to cryogenic temperatures.

The corrosion struggle of Alloy 316H is comparable to Alloy 316/316L and is better to Alloy 304/304L in moderately caustic environments. It is often used in procedure streams containing chlorides or halides. The alloy resists atmospheric corrosion, as well as, fairly oxidizing and falling environments. It also resists corrosion in impure marine conditions.

SS 316H Flanges is non-magnetic in the annealed condition. It cannot be hard-bitten by heat treatment; however, the substance will harden due to cold working. It can be simply welded and processed by normal shop fabrication practices.

Alloy 316H also has good quality resistance to pitting in phosphoric and acetic acids. In most instances, the corrosion battle of Alloy 316H will be similar to Alloy 316/316 and will have better corrosion resistance to Alloy 304/304L. Procedure environments that do not attack Alloy 304/304L will not assault this grade. One exception, however, is in extremely oxidizing acids such as nitric acids wherever Stainless steels contain molybdenum are fewer resistant. Alloy 316H performs well in sulfur-containing service such as that encounter in the pulp and paper manufacturing. The alloy can be used in elevated concentrations at temperatures up to 120°F (38°C).

Alloy 316H be able to be welded by most standard processes. A post weld heat treatment is not essential.

Equivalent Grades