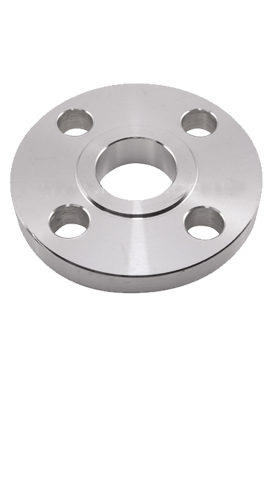

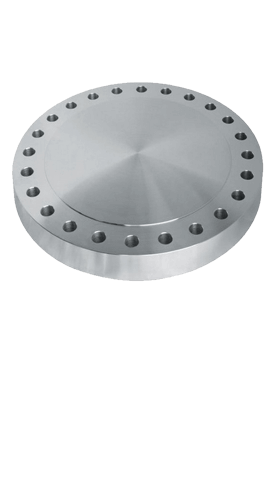

Inconel 625 Lap Joint Flanges, ASTM B564 Inconel 625 Socket weld Flanges, Inconel Alloy 625 Flanges Supplier, Inconel 625 Flanges Exporter, Inconel 625 Slip on Flanges, Inconel 625 Blind Flanges, Inconel 625 Weld Neck Flanges, Inconel Alloy 625 Flanges in Mumbai, India.

Dinesh Tube India is one of prominent distributor and supplier of Inconel 625 Flanges. We provide flanges in various ferrous and nonferrous grades. We are an ISO certified company that delivers a whole range of flanges considering the national and international standards. Inconel 625 Flanges are composed of nickel, molybdenum and chromium content. It is used for its high strength, toughness, corrosion and oxidation resistance.

Inconel 625 Pipe Flanges, ANSI B16.5 Inconel Alloy 625 Spectacle Blind Flanges Supplier, Inconel 625 Long Weld Neck Flanges, Inconel 625 RTJ Flanges, ASME SB564 Inconel 625 Threaded Flanges Stockists, Inconel Alloy UNS N06625 Flanges in India.

These are derived from the stiffening effect of molybdenum and niobium content chromium- nickel matrix. However, these flanges are developed for high-temperature applications. Its high alloyed composition provides a high level of general corrosion resistance. These flanges are also resistive scaling in at elevated temperatures.

It is superior many temperatures high temperatures under cycling heating temperatures. The high alloy content enables to withstand in the variety of severely corrosive environments. There is no attack of mild environments. It has the high molybdenum content makes flanges very resistance to pitting and crevice corrosion. These flanges are manufactured by hot or cold forming process using the advanced machines. To get extra strength Inconel flanges are cold worked.

Our key in business is complete customer total satisfaction with products. We build quality objectives at appropriate levels to ensure the requirements of the customers. We provide our customer's products with appropriate documentation. Those reports are product invoice, specification guide, fumigation reports, packing details like net and gross weight, quantity and marks and number, NABL test report, MTC report as per EN 10204 3.1 or 3.2 and guarantee letter. Other reports are Certificate origin by us, raw material test report, mill test report, quality assurance plan, and heat treatment charts.

We perform different tests for quality assurance those tests are destructive test/ non destructive test, mechanical test, hardness test, tensile test, positive material test, chemical test/ spectro analysis, intergranular corrosion test, ultrasonic test, radiographic test, pitting corrosion test and visual inspection. The standard packaging techniques used for damage-free shipping of products. Those are wooden crates, cartons, cases, and pallets with a thin covering of plastic. One can order special Inconel 625 Flanges as per their application requirements from us.

Equivalent Grades