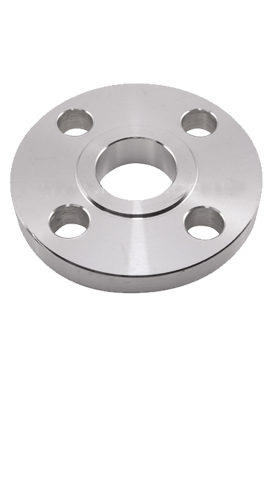

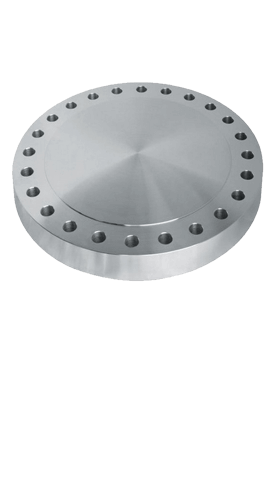

Inconel Alloy 600 Flanges, Inconel 600 Flanges Exporter, Inconel 600 Blind Flanges, Inconel 600 Slip on Flanges, Inconel 600 Lap Joint Flanges, Inconel 600 Weld Neck Flanges, Inconel Alloy 600 Flanges Supplier, ASTM B564 Inconel 600 Socket weld Flanges in Mumbai, India.

Dinesh Tube India is one of the prominent suppliers, traders, and distributors of high-quality Inconel 600 Flanges. Our industrial Inconel flanges are manufactured with the finest raw materials and précised for quality and performance, also used in diverse industries. The quality and performance of our products are the basis for the growth and success of our business. We tend to offer innovative products to customers.

ANSI B16.5 Inconel Alloy 600 Spectacle Blind Flanges Supplier, Inconel 600 RTJ Flanges, Inconel Alloy UNS N06600 Flanges, Inconel 600 Pipe Flanges, ASME SB564 Inconel 600 Threaded Flanges Stockists, Inconel 600 Long Weld Neck Flanges in India.

Inconel 600 Flanges include nickel, iron, and chromium flanges. It is a solid solution-strengthened alloy used for applications that require high-temperature stability and corrosion resistance. The service temperature of an alloy can be used for cryogenic temperatures up to 2000 degrees F. These flanges have excellent mechanical properties, and high nickel composition gives resistance to corrosion by many organic and inorganic compounds and makes it virtually immune to chloride stress corrosion cracking. It has a desirable combination of high strength and good workability in adverse environments.

This alloy's versatility is used in various applications involving temperatures from cryogenic to above 1095 degrees C. These flanges are used extensively in chemical processing, such as chlorides, sulfides, alkalis, phosphoric, nitric, and other harsh acids. This alloy's strength and oxidation resistance at high temperatures make it useful for many applications in heat-treating industries.

These flanges can be both cold and hot-formed using a typical process. The hot working process is performed in the temperature range between 1600 – 2250 degrees F. And higher temperatures can decrease the elasticity. Also, the standard welding processes can achieve welding methods. The annealing of flanges can be performed at 1850 degrees F. It has better corrosion resistance and higher tensile, impact, and fatigue properties.

Multiple tests are conducted and followed by professionals under the norms of international standards before delivering the product to our customers. The tests include Positive material, destructive/non-destructive, mechanical, hardness, tensile, micro, macro, chemical, and intergranular corrosion tests. Other tests are flaring test, ultrasonic test, radiographic, pitting corrosion test, and visual inspection.

Equivalent Grades